Die-cutting is a broad term, but in crafting, the act of die-cutting refers to a process in which you use a machine to mass-produce cut-out shapes. You can create the same shape, with the exact same dimensions, over and over again without using scissors, stencils, or a craft knife. It saves time and makes your cut-out shapes look professional and consistent every time. In die-cutting, dies are metal-shaped objects with a raised, sharp area for cutting.

Die is a tool or device used for imparting a desired shape, form, or finish to the material. Examples include a perforated block through which metal or plastic is drawn or extruded, the hardened steel forms for producing the patterns on coins and medals by pressure, and the hollow molds into which metal or plastic is forced. Tool and die making is the industrial art of manufacturing stamping dies, plastics molds, jigs, and fixtures to be used in the mass production of solid objects.

A major advantage of die-cutting is its versatility as a fabrication method. The process depends upon the shape and configuration of an interchangeable die. Specialized dies may be used for specific projects, such as those involving bending, coining, or curling. Generally, the name of the operation is signified by the type of die used in it. Accute Laser Die Pvt Ltd is an experienced tool and die company that designs and builds tools and dies in-house. Our state-of-the-art facility also provides replacement die components, fixtures, and gages as well as manufactured assemblies.

Die cutters and die-cutting machines convert web or sheet materials into shapes. They are used to process woven cloth, non-woven textiles, and rubber sheets. There are two basic types of die cutters and die-cutting machines: clicker presses and rotary die cutters. Clicker presses are used in the manual conversion of web materials and include switches, pendants, and pushbutton controls, and are used for more demanding applications. Rotary die cutters or roller press die cutters, are used in the high-speed conversion of web and sheet materials. These machines press roller-shaped cutting dies against a web. As the roller die rotates, web materials are inserted and then converted into shapes.

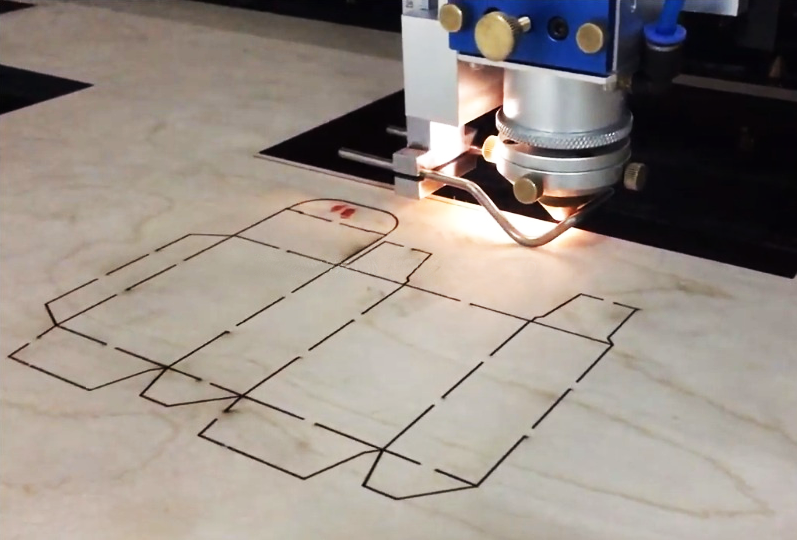

Laser die-cutting is a highly technical process that uses a laser to cut materials into various pre-designed forms. It is mostly used for industrial manufacturing applications, but can also be used by small businesses or hobbyists to create all manner of objects.

A laser die-cut operates by directing the output of a high-power laser beam to the material requiring cutting via a computer that has the product’s pre-set CAD-generated design and dimensions inputted beforehand.

Lasers can be used to make a variety of cuts and do not require any contact with the material. It can cut through intricate, tricky patterns in which it would be difficult with other techniques. There is a wide range of lasers so they can match up with a variety of materials. A laser will last significantly longer.

Embossing is the process of placing a flat part in between a male and female embossing die set. Once the part is pressed by the male and female dies, the image or characters are raised above the level part, similar to the numbers on a credit card. Accute Laser Die private limited manufactures Embossing Die sets by utilizing state-of-the-art CNC Electrical Discharge Machines (EDM) to yield the sharpest, crispest, and most long-lasting die images. Customized artwork appears directly on the die. The ability to reuse a die and repeat an image from piece to piece is maintained very well.

Through die-casting processes, demanding components can be economically manufactured. The progress made in die-casting technology, project partnerships, energy, and cost-efficient machines and the possibilities that arise from digitized production help die-casting foundries assure and enhance their competitiveness. We have succeeded in recognizing and meeting them for production and application of die-cast components have achieved long-term success.